Farm & Ranch

A Steady Tradition

More than a century ago, a rugged, wild, and western stretch of land became, seemingly overnight, the site of Oklahoma’s first major industry.

Its legacy began shortly after statehood in 1907. Oklahoma City Chamber of Commerce members and fellow businessmen were searching for ways to bring more revenue to their city. They’d seen other major cities flourish with the presence of stockyards and envisioned the same for the fledgling state. With a prosperous future in mind, they decided to approach several of the major packing houses.

“The city fathers were looking at bringing in new industry, because everything was concentrated downtown. They secretly recruited packing houses in Chicago and Omaha because of the bustling business,” noted Kelli Payne, Oklahoma National Stockyards Yards Liaison and President of Stockyards City Mainstreet.

Chamber of Commerce President Sidney Brock sent letters to the largest packing houses, and soon Thomas Wilson, Executive Vice President of the Nelson Morris Company headquartered in Chicago, traveled south to see what Oklahoma City had to offer.

According to Payne, tall tales and stories surround the initial visit. “Obviously just getting someone here from Chicago would be a feat in the early 1900s. I can’t vouch for authenticity, but there’s a story that at the time there was only one available automobile in downtown Oklahoma City, and they borrowed it. As the crow flies, it’s only two miles from downtown to the Stockyards, but it took them two days to get there,” she explained. “There was no highway at the time. The Oklahoma River would have been raging, plus there was quicksand and plum thickets that they had to contend with.” One account notes that the passengers in the car spent a good bit of time pushing it out of ruts and mud.

While there might have been obstacles, the delegate from Chicago liked what they saw – but they still had big demands for the city. “These packinghouses knew what they could do. They knew how many cattle they could process in a day and how many employees they would hire, and they knew what an impact they would have on the city, so they had a long list of concessions,” Payne said. “The numbers were staggering. They needed 350,000 gallons of water a day for five years, because they would be using it constantly to clean and water cattle, and they needed it brought right to the gate. They also wanted a $300,000 bonus, a five-year tax exemption, sewer, electric, and street car lines, a railroad, and land adjacent to the North Canadian River.”

Oklahoma City councilmen met the demands of the Nelson Morris Company, and soon Schwarzchild and Sulzberger came to town under similar terms, and more followed. Morris connections constructed the necessary Oklahoma National Stockyards and established the Oklahoma Stockyards National Bank.

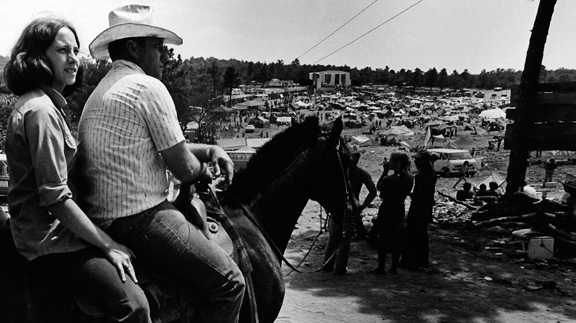

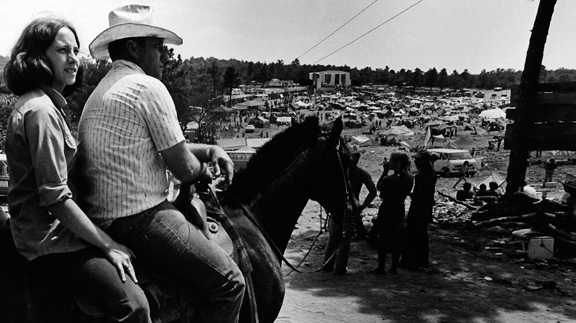

The Stockyards began operations in October of 1910 and represented the heaviest concentration of labor in the capitol city. The once desolate area boomed overnight, creating 2,400 new jobs in a city of 60,000. The area soon became known as Packingtown.

“A whole city sprang up. Hotels, a post office, banks, restaurants, grocery stores, hat makers, and anything you could imagine. A lot of guys that worked in the packing houses would work twelve hour shifts. Two would share a room, and when they’d leave for work, two different workers would come in and use their room.” Payne added, “It was a different lifestyle than what we enjoy today.”

Livestock began arriving by rail or cattle drive. At the time, the cattle were traded private treaty through the service of the many on-premise commission companies. Catwalks crisscrossed across the pens, and the sellers would make deals above. Soon the cattle would be loaded back on the trains and sent to the different packing houses; while some were close, some were a few miles away.

Big changes came in the early 1960s. Many other major stockyards had gone the route of live auctions, abandoning the practice of private treaty sales. “There’s another fable, and I’m sure there’s truth in there somewhere. There was a younger gentleman that was working in the stockyards. He went to the local clothing store and purchased a brand new set of overalls and a white button down shirt and hoped a train to Kansas City to see what the live auctions were all about,” Payne said.

That young man returned filled with excitement and convinced some other owners to try the live auction. Since they needed a place to hold the sales, the large barn that stored hay was renovated with an auction area and lobby and is still in use today.

Within a few months it was evident that the live auction method was there to stay. The auction provided competition for available livestock, and more growth followed. Today, the Stockyards handle cattle exclusively, but in its early years hogs, sheep, horses and mules also trotted across the bricks.

By 1966, the Oklahoma National Stockyards was one of the largest markets in the nation, representing approximately $125 million in annual business. In 1973, the number of saleable cattle rose to more than 900,000, and the Stockyards took the nation’s lead.

Unfortunately, the industry that created the need for the stockyards, the meat packing plants, were having a major business decline, and one-by-one, they closed or moved to other locations, resulting in a decline in receipts at stockyards across the country.

Payne added that, while the Oklahoma National Stockyards has had many years with nearly one million head of cattle passing through the arch, video sales and people contracting cattle directly to the feed yard have also contributed to the lower – but still strong numbers.

“There are other sale barns that, maybe over a year will move more cattle, but historically speaking, over the course of time we would be tough to beat,” Payne explained. “This past year we ran just under 400,000 head over cattle through the sale barn. Week in and week out we’re pretty strong.”

That strength is attributed to several factors, including the proximity to major interstates and highways, as well as feedlots in Texas and Kansas. “Our location is the best. There are cattle to the north, south, east and west, and we’re right in the middle,” Fisher said. “We also take care of our customers. We cater to the big companies as well as the small ranchers. It doesn’t matter if they bring 500 cattle or five, because we’ll take care of them.”

Fisher also noted that the schedule of selling cattle on Monday and Tuesday helps to draw in more sellers. “I think it helps because many of our customers have jobs, and they like that they can bring in cattle over the weekend,” he said.

The economic impact of the Stockyards can literally stretch across the country. “I’ve tried to pin it down. If you look at the impact here in Oklahoma City, you’re only looking at a small piece of the equation. It actually goes coast to coast,” Payne said. “For example, a couple times a year it gets really popular for Florida cattle to come to town, so if you look at it, they could be loaded in Florida and make the drive to Oklahoma City. They driver will have to buy fuel and food or maybe lodging, and they need the same once they get to Oklahoma City. Those cattle the driver brought could then be purchased and be in California within just a few days.”

While the Oklahoma National Stockyards employs between 20 to 30 people at a time, there are approximately 300 that make their living because of it. This includes employees of commission companies, and other companies located behind the arch.

Although droughts, floods, and other factors have caused fluctuations in the market, the Oklahoma National Stockyards has continued its steady tradition of the cattle business. “We were flooded with cows during the drought. We’re still trying to catch up on sleep because the cows just kept coming. Owners were out of hay, feed, and water, and they had no choice but to sell,” Payne recalled.

Learn more about the Oklahoma National Stockyards in the April issue of Oklahoma Farm & Ranch.

Farm & Ranch

Cattle Nematodes (Worms)

Barry Whitworth, DVM | Senior Extension Specialist | Department of Animal & Food Sciences

According to the Mesonet, Oklahoma received some much-needed rain in late April (2023). With the moderate temperatures and high humidity, the environment is perfect for the proliferation of gastrointestinal nematodes (GIN) which are commonly called “worms.” Cattle can be infected with a variety of GIN. Most do not cause issues unless husbandry practices are poor. However certain GIN have been associated with disease. The most pathological GIN in cattle is Ostertagia ostertagi. Cooperia species and Haemonchus species are two that have been implicated with production issues. Control of these parasites is constantly changing due to environment, anthelmintic (dewormer) resistance, and consumer preference. Cattle producers should develop a plan to manage these parasites.

In order for GIN to complete their life cycle, certain environmental conditions must exist. The development stage begins with passing of the egg in the feces of the animal. If the egg is to hatch, the temperature must be warm and the humidity needs to be close to 100%. Ideal temperature ranges from 70⁰ to 80⁰ Fahrenheit (F), but any temperature above 45⁰ F will allow for development. Temperatures above 85⁰ F or below 45⁰ F will begin to hamper development. Humidity needs to be 80% or higher.

Once the egg hatches, the larva goes through a couple of molts to reach the infective stage which is the third stage larva (L3). L3 must have moisture to free itself from the fecal pat. Once free, it rides a wave of water on to a blade of forage. Once ingested, this begins the prepatent or pre-adult stage. Two molts take place during this stage (L3 to L4 and L4 to L5). If conditions are not favorable for survivability of offspring, L4 will go into an arrested development stage (hypobiosis) for a period of time. The patent or adult stage is the mature breeding adult.

Once inside the body, the parasite will migrate to certain locations in the digestive tract. For example, O. ostertagi develop in the gastric gland in the abomasum. H. placei and H. contortus will migrate to the abomasum. Cooperia species will live in the small intestine. A few like Trichuris (whipworms) are found in the large intestine.

Clinical signs of parasitism vary according to the species of parasite, burden, and site of attachment. Severe disease, which is referred to as parasitic gastroenteritis (PGE), with internal parasites is unusual with today’s control methods. Clinical signs of PGE are lack of appetite, weight loss, weakness, diarrhea, submandibular edema (bottle jaw), and death. However, most parasite infection are subclinical which means producers do not see clinical signs of disease. In subclinical infections, the parasite causes production issues such as poor weight gain in young cattle, reduced milk production, and lower pregnancy rates.

Producers should be monitoring their herds for parasites throughout the year but especially in the spring when conditions are ideal for infection. A fecal egg count (FEC) is a good way of accessing parasite burdens. Livestock producers need to gather fecal samples from their herd periodically. The samples should be sent to their veterinarian or a veterinary diagnostic lab. Different techniques are used to access the number of eggs per gram of feces. Based on the counts, the producer will learn the parasite burden of the herd. Producers can use this information to develop a treatment plan.

In the past, GIN control was simple. Cattle were routinely dewormed. Unfortunately, anthelmintic resistance has complicated parasite control. Now proper nutrition, grazing management, a general understanding of how weather influences parasites, biosecurity, refugia, anthelmintic efficiency, and the judicious use of anthelmintics are important in designing an effective parasite management program. All of these considerations need to be discussed in detail with a producer’s veterinarian when developing a plan for their operation.

Cattle producers need to understand that parasites cannot be eliminated. They must be managed with a variety of control methods. Designing a parasite management plan requires producers to gain a general understanding of life cycle of the parasite as well as the environmental needs of the parasite. Producers should use this information as well as consult with their veterinarian for a plan to manage GIN. For more information about GIN, producers should talk with their veterinarian and/or with their local Oklahoma State University Cooperative Extension Agriculture Educator.

References

Charlier, J., Höglund, J., Morgan, E. R., Geldhof, P., Vercruysse, J., & Claerebout, E. (2020). Biology and Epidemiology of Gastrointestinal Nematodes in Cattle. The Veterinary clinics of North America. Food animal practice, 36(1), 1–15.

Navarre C. B. (2020). Epidemiology and Control of Gastrointestinal Nematodes of Cattle in Southern Climates. The Veterinary clinics of North America. Food animal practice, 36(1), 45–57.

Urquhart, G. M., Armour, J., Duncan, J. L., Dunn, A. M., & Jennings, F. W. (1987). In G. M. Urquhart (Ed). Veterinary Helminthology. Veterinary Parasitology (1st ed., pp 3-33). Longman Scientific & Technical.

Farm & Ranch

The Value of Vitamin A

Barry Whitworth, DVM – Area Food/Animal Quality and Health – Specialist for Eastern Oklahoma

A ranch in Australia experienced an abnormally high number of stillbirths and weak born calves in 2004-2005. An investigation revealed that the usual infectious causes were not the problem. After additional testing, veterinarians diagnosed low levels of vitamin A as the cause.

According to Dr. Greg Hanzlicek, with the Kansas State Veterinary Diagnostic Laboratory (KSVDL), Kansas had an unusually high number of stillbirth cases and weak born calves in the spring of 2019. After many laboratory tests, it was concluded that the problem stimmed from a lack of energy, protein, Vitamin A, or combinations of all of these.

Both of the above examples demonstrate the importance of vitamin A in reproductive efficiency. Research has shown that low vitamin A levels during pregnancy are associated with abortions, stillbirths, and weak born calves. In addition to playing an important role in reproductive efficiency, vitamin A is essential for vision, bone growth, and maintaining epithelial tissue such as skin and hooves.

Animals obtain vitamin A from consuming green forage and/or the addition of vitamin A supplements to the diet. Lush green pastures contain high amounts of vitamin A. As plants mature and during times of drought, the amount of vitamin A decreases. The ranch in Australia experienced below average rainfall in the previous two years prior to the calving season. During the calving season, rainfall was below average with very dry conditions and little green forage was available.

In general, animals obtain adequate amounts of vitamin A by grazing green forage. Animals grazing green pastures will build a healthy store of vitamin A in the liver. When vitamin A is in short supply, the stores in the liver prevent deficiencies. According to Dr. Lalman, Extension Beef Cattle Specialist Oklahoma State University, the stores should last 2 to 4 months during times of deficiency. During times when green forage is not available, vitamin A supplements need to be added to the diet to prevent deficiencies.

When vitamin A levels are deficient, night blindness is one of the earliest clinical signs. Other eye issues include clouding of the cornea, ocular discharges, and possible ulcerations. Skin issues found when levels of vitamin A are deficient include a dry rough coat, scales on the skin, and dry cracked hooves. Other neurological signs include incoordination or gait problems. Seizures may occur due to the increase cerebrospinal fluid pressure. Birth defects have also been attributed to low vitamin A levels.

Animals displaying vitamin A deficiency should be treated immediately with vitamin A injections. If treated early, response is usually rapid and complete. However, delaying treatment may result in irreversible damage. Even with treatment, cattle with vision impairment due to vitamin A deficiency may not regain their sight.

Preventing Vitamin A deficiency depends on producers being attentive to the environmental conditions that favor low vitamin A levels in forage. During these times, producers need to supplement the diet with vitamin A. Producers need to be aware that Vitamin A supplements degrade rapidly, so vitamin A supplements should not be stored for long periods of time. In addition to vitamin A supplementation, research indicates that diets low in protein result in poor absorption of vitamin A. It is important that producers ensure that the rations have sufficient protein levels. Lastly, since colostrum contains high levels of vitamin A, producers need to ensure that newborns obtain adequate amounts of colostrum at birth.

Similar to the Australian example, most of Oklahoma had below average rainfall for the year of 2022. This resulted in pasture quality decreasing earlier than normal. Due to this year’s lack of green forage, liver stores of vitamin A may be inadequate for the animal’s needs. Producers need to ensure that the diets of their cattle have adequate amounts of vitamin A, energy, and protein. For more information about Vitamin A, producers should contact their veterinarian and/or visit with their Oklahoma State University County Ag Educator.

References

Hanzlicek, G. (2019, May). Difficult Calving Season Findings:2019. Diagnostic Insights. www.ksudl.org/resources/news/diagnostic_insights/may2019/difficult-calving-season2019.html.

Hill, B., Holroyd, R., & Sullivan, M. (2009). Clinical and pathological findings associated with congenital hypovitaminosis A in extensively grazed beef cattle. Australian Veterinary Journal, 87(3), 94–98.

Parker, E. M., Gardiner, C. P., Kessell, A. E., & Parker, A. J. (2017). Hypovitaminosis A in extensively grazed beef cattle. Australian veterinary journal, 95(3), 80–84.

Farm & Ranch

Lice in Cattle

Barry Whitworth, DVM, MPH | Senior Extension Specialist

Department of Animal & Food Sciences | Freguson College of Agriculture | Oklahoma State University

Cattle lice cost Oklahoma cattlemen millions of dollars each year in decreased weight gains and reduced milk production. If cattle producers have not treated their cattle for lice this fall, they need to consider what type of lice control to initiate. This is especially true for cattle producers that had problems in the previous year. Cattle producers should monitor cattle closely during the months of December, January, and February. Producers should not wait until clinical signs appear before beginning treatment.

The life cycle of the different species of cattle lice are very similar. The life cycle begins with the female louse attaching her egg to a shaft of hair. The egg will hatch as a small replica of the adult. After several molts, the adult will emerge. The cycle takes around 3 to 4 weeks to complete. These newly hatched lice will spend their entire life on the host and are host specific which means cattle cannot be infected with lice from other animals.

Small numbers of lice may be found on cattle in the summer, but high populations of lice are associated with cold weather. Since cattle tend to be in closer proximity to each other in the winter, lice can spread easily between cattle. A small percentage of cattle tend to harbor larger numbers of lice. These animals are sometimes referred to as “carrier animals”, and they may be a source for maintaining lice in the herd. As with many other diseases, stress also contributes to susceptibility and infestation.

Signs of lice infections in cattle are hair loss, unthrifty cattle, and hair on fences or other objects. If producers find these signs, they may want to check a few animals for lice. They can check for lice by parting the hair and observing the number of lice per square inch. If an animal has 1 to 5 lice per square inch, they are considered to have a low infestation. Cattle with 6 to 10 lice would be considered moderately infested. Any cattle with more than 10 lice per square inch are heavily infested.

Cattle have two types of lice. One type is the biting or chewing louse. These lice have mouth parts that are adapted to bite and chew the skin. The second type is sucking louse. These lice have mouth parts that will penetrate the skin and suck blood and other tissue fluids. It is not uncommon for cattle to be infested with more than one species of lice.

The biting or chewing louse is Bovicola (Domalinia) bovis. This type of lice feeds on hair, skin, skin exudate, and debris. Typical clinical signs with this type of louse are hair loss, skin irritation and scabs on the skin. They are found on the shoulders and back.

Four types of sucking lice can be found in the United States. The first is the “short nose” louse or Haematopinus eurysternus. This is the largest cattle louse. This louse is found on the neck, back, dewlap, and base of the tail. The second is the “long-nose” louse or Linognathus vituli. This louse is bluish in color with a long slender head. This louse is found on the dewlap, shoulders, sides of the neck, and rump. The third is the “little blue” louse or Solenoptes cappilatus. This louse is blue in color and is the smallest cattle louse. This louse is found on the dewlap, muzzle, eyes, and neck. The last is the “tail” louse or Haematopinus quadripertuses. This louse has been found in California, Florida, and other Gulf Coast States. This louse is found around the tail.

The sucking lice have the potential to cause severe anemia if the numbers are high. This can result in poor doing cattle or in extreme cases death. They also can spread infectious diseases. The long-nose louse has been found to be a mechanical vector for anaplasmosis.

Prevention of lice infestation should begin in the fall. Producers should not wait for clinical signs to appear before beginning treatment. Several products are available to control lice. Producers should read and follow the label directions. Producers should keep in mind that many of the lice control products require two administrations to control lice. Failure to do this may result in cattle having problems with lice infestations.

Some producers have complained that some products do not work. These complaints have not been verified; however, this is a good reason to consult with a veterinarian for advice on what products to use. Most treatment failures are associated with incorrect application not resistance. Proper application of Pour-On insecticides is to administer from the withers to the tailhead. Also, the proper dose is essential for good control.

Cattle producers need to consider a few other things in lice control. Since cattle in poor body condition are more prone to lice infestation, producers need to be sure that the nutritional needs of their cattle are being met. Cattle that have a history of lice infestations should be culled. Lastly, any purchased cattle need to be inspected for lice before entering the herd. If lice are found, the animals should be isolated and treated before entering the herd.

If producers would like more information on lice in cattle, they should contact their local veterinarian or Oklahoma State University County Extension Agriculture Educator. They may also want to read Oklahoma Cooperative Extension Fact Sheet Beef Ectoparasites VTMD-7000 at https://extension.okstate.edu/fact-sheets/beef-cattle-ectoparasites.html.

-

Attractions8 years ago

Attractions8 years ago48 Hours in Atoka Remembered

-

Country Lifestyle9 months ago

Country Lifestyle9 months agoJuly 2017 Profile: J.W. Hart

-

Country Lifestyle9 years ago

Country Lifestyle9 years agoThe House a Treasure Built

-

Country Lifestyle4 years ago

Country Lifestyle4 years agoThe Two Sides of Colten Jesse

-

Outdoors7 years ago

Outdoors7 years agoGrazing Oklahoma: Honey Locust

-

Equine8 years ago

Equine8 years agoUmbilical Hernia

-

Outdoors5 years ago

Outdoors5 years agoPecan Production Information: Online Resources for Growers

-

Farm & Ranch7 years ago

Farm & Ranch7 years agoHackberry (Celtis spp.)