Country Lifestyle

Get to Know Jacob Custer

On a Sunday afternoon, November 3, 2019, Aaron and Debby Custer, received the call every parent prays they will never receive. Their middle child and only son Jacob, had been in a feed mill accident and was being life flighted to Amarillo, Texas. Aaron and Debby had spent the weekend in Hugo, Oklahoma with Aarons parents, Warren and Marilyn Custer, and were over 400 miles from Amarillo when the call came in. As a mother I can only imagine the fear in their hearts as they made the long trip from Hugo to Amarillo keeping up with Jacob’s condition through phone calls and texts.

The day of the accident was like any normal day at the feedlot. Jacob had rode the one-man electric lift up to the top of the mill to check out an airlift (an air system that moves/blows the feed ingredients used in mixing the feed rations) located over the top of the auger cover. As Jacob was working on top of the auger cover to access the airlift which was just out of is reach, his left toe caught the lid and flipped it off causing Jacob’s left leg to land into the auger. I truly believe with every ounce of my being, in the split second when Jacob could have lost his life, God reached down and gave Jacob the physical and mental strength, needed to free himself from the clutches of the auger.

After Jacob had managed to free himself from the auger, he used his shredded jeans to make a tourniquet then called his Supervisor and told him he had just cut his leg off and needed help. Upon his Supervisor’s arrival, Jacob instructed him to take off his shirt in order to construct another tourniquet. Working together the two used the shirt and a latch bar to secure an additional tourniquet. With the help of his Supervisor, Jacob hopped to the one-man lift and rode it down all alone where he was meet with the crew he worked with. Prior to the arrival of the paramedics and life flight helicopter, two more tourniquets were tied to his left leg to try and stop the bleeding.

Upon arrival to the hospital the Doctors discovered that Jacobs leg had been disarticulated at the joint, or in layman’s terms, it had been twisted off at the knee. After the initial surgery, an infection set in and an additional three to four inches more of Jacob’s leg had to be taken off. Jacob spent a total of 25 days at the hospital in Amarillo, Texas, with his mom Debby rarely leaving his side.

Jacob ended up having a total of seven surgeries before being released to go back to Oklahoma where he did inpatient rehab in Ardmore, OK. During his two weeks at Mercy Rehabilitation Services, in Ardmore, Jacob worked on building up and getting back his core strength, which after 25 days of laying in a hospital bed, had started to deplete. After the two weeks of in-house rehab, Jacob was able to go home with his parents while he attended outpatient rehab.

Also, during his time of rehabilitation, Jacob regularly went to Mercy Hyperbaric and Wound Care to tend to the healing of his leg. A wound vac (a device that creates negative low atmospheric pressure at a constant rate. It is used on open wounds to remove fluid secretion and enhance granulation tissue and wound healing) was placed on the stump of Jacob’s leg and was not taken completely off until April 10, 2020. After the removal of the wound vac Jacob started working with Dream Team Prosthetics to get his artificial limb. Jacob said he loved working with the Dream Team. He said they were extremely professional and a just a great bunch to work with.

When working on the design for the prosthetic limb, the Dream Team designed the leg to fit Jacob’s lifestyle. Knowing Jacob would be working in a feedlot again, the prosthetic needed to be water and dust proof. The technology in the knee of the prosthetic was originally created for wounded combat veterans by Ottobock, a company out of Germany. Ottobock was hired by the DOD to create prosthetics that would allow wounded soldiers to return to active duty. The technology includes a microprocessor that records the knee’s position 100 times each second. The information is then sent to a hydraulic unit that can adjust resistance. In a nutshell the knee allows Jacob to walk down a ramp, up and down stairs and do most anything his natural leg would do. The leg also comes with six different programable modes which allow for different actions such as walking, running, or driving.

During the recovery Jacob had to overcome more than just the normal healing process. He had to learn once again how to be mobile. How to get in and out of bed or a wheelchair, how to use crutches etc., In addition to healing and mobility Jacob experienced what is known as phantom pains along with the actual nerve pain. He said the nerve pains were the worse but still today experiences phantom symptoms such as a sensation of his foot itching. Jacob said the lowest points during his journey where the nights at the hospital when he couldn’t sleep. Those nights were tough, but the mental battle was the hardest to conquer.

When I asked Jacob, what kept him motivated his answer was simple. He said from the day the accident happened he kept telling himself he wanted to go back to work for the feed yard. Over the last several years he has really come to love the cattle feeding industry and plans to continue his career in the cattle feeding world. The old age saying of, if you love your job you will never work a day in your life fits Jacob to a “T”!

Accidents are a normal part of any industry, however in the agriculture industry it seems like we hear of more severe injuries from machinery and tools such as augers. I asked Jacob if he felt the accident could have been prevented or if more safety measures should be put in place. Jacob’s said he felt a large majority of accidents could be prevented with the proper behavior put in place, but complacency will get you every time. He said you can build a cage around a bomb but that won’t keep some one from cutting it open and punching the red button. At the end of the day your safety is in your own hands and you are the only one who will deal with the consequences of your actions. Before you start every workday remember why you work, or who you work for (i.e. family, friends) and think of them before you do something perilous just to shave time.

I am a firm believer, that with every negative there is a positive. When I asked Jacob if he felt there was a positive from his accident, he said absolutely. Jacob said the accident had allowed him to spend more time developing himself as a person and changed his perspective on a lot of things. He said he now has a more positive outlook on life these days and shared with me a quote by Ray Wylie Hubbard he once saw that really stuck with him throughout the entire ordeal. The quote is “On days where my gratefulness exceeds my expectations, I have good days.”

Jacob’s advice to others who have lost a limb, “don’t give up!” It’s hard but you’re only limited by what you tell yourself you can’t do. There are people everywhere who will support you on the journey, and just know there’s a whole lot of life after limb loss.

After almost loosing his life that dreadful day in November, Jacob returned this past June to the same feedlot he last left on a life flight. Jacob is back living his life doing what he loves and I for one will always be grateful God granted him another chance. Having known Jacob since the day he was born I always knew he was special with his kind ways, big heart and special gift of gab. I just never knew the inner strength that lay quietly inside.

Until Next Time …

Read more in the November 2020 issue of Oklahoma Farm & Ranch.

Country Lifestyle

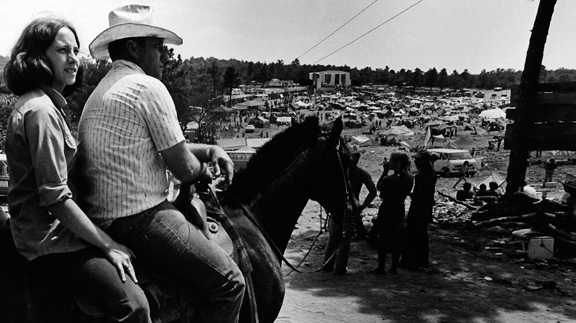

Riding for the Brand

By: Christopher Dysinger

According to the Code of the West a man who has integrity is one who rides for the brand. If you are unfamiliar with cowboy parlance this phrase is used to describe being loyal to the outfit you work for. Cowboys were, “intensely loyal to the outfit they were working for and would fight to the death for it. They would follow their wagon boss through hell and never complain.” -Teddy Blue Abbot. Riding for the brand means being loyal and when I consider what it means to be loyal I am reminded of the words of the Lord Jesus to His disciples in Matthew 16:24, “Then said Jesus unto His disciples, If any man will come after Me, let him deny himself, and take up his cross and follow Me.” To me, to take up the cross and follow the Lord is the epitome of what it means to ride for the brand.

When you place your trust in the Lord Jesus you are signing on to His outfit, to speak the language of the West. When you called upon the name of the Lord Jesus by faith, He saved you and from this point you are riding for His brand. In taking up your cross and following Him you have pledged to be loyal, and this means you face any hardship or trial like a cowboy on the trail moving the herd. Any complaint must be swallowed in the same way you would swallow a cup of coffee. When I hear our faith and loyalty to the Lord Jesus put into these terms it stirs something within me that moves me to keep right on riding for the brand.

Louis L’amour wrote, “Riding for the brand was an expression of loyalty to a man’s employer or the particular outfit he rode for. It was considered a compliment of the highest order in an almost feudal society. If a man didn’t like a ranch or the way they conducted their affairs he was free to quit, and many did; but if he stayed, he gave loyalty and expected it. A man was rarely judged by his past only by his actions. Many a man who came west left things behind him he would rather forget, so it was not the custom to ask questions. Much was forgiven if a man had courage and integrity and if he did his job. If a man gave less than his best, somebody always had to pick up the slack, and he was not admired.” It is the same when a person gives his or her heart to Jesus.

When you come to the Lord Jesus you are not judged by your past. When you come to the Lord Jesus, repenting of sin and seeking forgiveness, everything from your past is left behind. All will be forgiven. 1 John 1:9 reads, “If we confess our sins, He is faithful and just to forgive us our sins, and to cleanse us from all unrighteousness.” When you place your faith in the Lord Jesus you are promising to be loyal and in return you will receive the same. He has promised that He will never leave us or forsake us. When you walk with the Lord Jesus through life you are indeed, “riding for the brand.”

“Riding for the brand” is not just an expression of loyalty nor is it just an expression of pride, it is also an expression of love. When a cowboy claims to be riding for the brand, he is telling any other outfit who may seek his loyalty, that he cannot give it, because he has given his word to another. It is the same when we pledge our faith and loyalty to the Lord Jesus. If any would call us away from Christ we cannot go, because we are riding for the brand.

The End

This article is an excerpt from the book, The Bible and the Code of the West by Dr. Christopher Dysinger.

Country Lifestyle

Farm Dogs & Table Scraps

What’s Safe and What’s Not?

Growing up on a farm, our dogs were tough. They roamed the pastures, slept under the barn, and ate just about anything they could get their paws on—whether we meant for them to or not. I’ll admit, I never thought twice when one of our old cow dogs snatched a biscuit off the table or licked up a spill from the barn floor. I’ve even seen a dog steal a whole rib bone off a plate and trot off like he’d won the lottery. And somehow, they always seemed fine.

But here’s the thing—just because they survived doesn’t mean it was safe. For every farm dog that lucked out, there’s another that wasn’t so fortunate. Some human foods can be downright toxic to dogs, and a little bit of bad luck (or a smaller, more sensitive dog) can turn a harmless snack into an emergency.

Common toxic foods lying around the farmhouse

If you’ve got a farm dog—or any dog, really—you need to be aware of the dangers lurking in everyday foods. Some of the biggest culprits include:

Chocolate – The darker it is, the worse it is. Even a little can cause vomiting, seizures, or worse.

Grapes & Raisins – No one’s exactly sure why, but they can cause kidney failure fast.

Onions & Garlic – In large enough amounts, these can destroy red blood cells, leading to anemia.

Xylitol (Found in Sugar-Free Gum & Candy) – This artificial sweetener can send a dog’s blood sugar crashing and cause liver failure.

Alcohol – Even small amounts can be deadly to dogs, affecting their nervous system much more than it does ours.

Bones from Cooked Meat – While not necessarily toxic, they can splinter and cause serious internal injuries.

Macadamia Nuts – These can lead to weakness, vomiting, and even paralysis in dogs.

What to do if your dog eats something toxic

First, don’t panic—but don’t ignore it either. If you know your dog ate something dangerous, call your vet immediately. They can tell you whether to induce vomiting or if it’s something that requires urgent care. If it’s after hours, contact the ASPCA Animal Poison Control Center (888-426-4435) or the Pet Poison Helpline (855-764-7661).

Prevention is always the best medicine, so keep toxic foods out of reach. That might mean keeping the trash can secured, making sure kids don’t slip the dog a treat under the table, or just being more mindful of what’s left on the counter.

Our farm dogs might have been lucky, but luck isn’t a great strategy when it comes to their health. A little awareness goes a long way in making sure they stay happy, healthy, and ready for the next day’s work.

For more information

ASPCA Animal Poison Control: www.aspca.org/pet-care/animal-poison-control

Pet Poison Helpline: www.petpoisonhelpline.com

Visit www.akc.org/expert-advice/nutrition/foods-your-dog-should-never-eat

Country Lifestyle

Summer Squash and Corn Chowder

By Lacey Vilhauer

Total time: 40 minutes

Servings: 6-7

Ingredients

- 6 slices bacon, cooked and crumbled and 1 1/2 Tbsp rendered bacon fat reserved

- 1 1/2 lbs yellow squash, chopped (about 3 medium)

- 2/3 cup thinly sliced celery

- 1 cup diced onion

- 1 Tbsp flour

- 2 cloves garlic, minced

- 2 3/4 cup milk (I used 1%)

- 5 cups canned or fresh cut corn (from about 6 ears corn), divided

- 1/2 cup heavy cream

- 1 1/2 tsp chopped fresh thyme (or 1/2 tsp dried)

- 3/4 tsp salt, then more to taste

- 1/4 tsp freshly ground black pepper, then more to taste if desired

- 3/4 cup shredded cheddar cheese, for serving

- Chopped green onion for garnish (optional)

Instructions

Heat 4 tsp reserved bacon fat in a large pot over medium-high heat. Add celery and onion and sauté 2 minutes then add the squash.

Saute until tender, about 6 minutes, adding in garlic and flour during last 2 minutes of sauteing. Reduce heat slightly.

Add 1 1/2 cups milk, 2 cups of the corn, thyme, salt and pepper to the sauteed veggies.

To a blender add remaining 3 cups of corn, remaining 1 1/4 cups milk and the cream. Process in blender until nearly smooth (about 30 seconds).

Add pureed mixture to pot and stir to blend. Cook until mixture reaches a light boil.

Serve warm with shredded cheese, crumbled bacon and sliced green onions if desired.

-

Attractions8 years ago

Attractions8 years ago48 Hours in Atoka Remembered

-

Country Lifestyle10 months ago

Country Lifestyle10 months agoJuly 2017 Profile: J.W. Hart

-

Country Lifestyle9 years ago

Country Lifestyle9 years agoThe House a Treasure Built

-

Country Lifestyle4 years ago

Country Lifestyle4 years agoThe Two Sides of Colten Jesse

-

Outdoors7 years ago

Outdoors7 years agoGrazing Oklahoma: Honey Locust

-

Equine8 years ago

Equine8 years agoUmbilical Hernia

-

Outdoors5 years ago

Outdoors5 years agoPecan Production Information: Online Resources for Growers

-

Farm & Ranch7 years ago

Farm & Ranch7 years agoHackberry (Celtis spp.)