Farm & Ranch

Our Flight to Hartsel

By Ralph Chain

I have known Jake Graham a long time. We bought a herd of Angus cows in Nebraska together and some other registered cows from Alfred Draton in the O’Neill, Nebraska, area. We also partnered on quite a few other cattle.

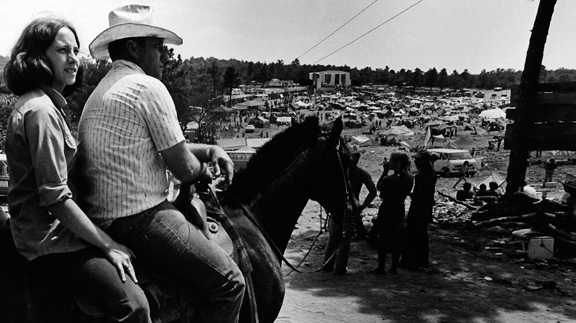

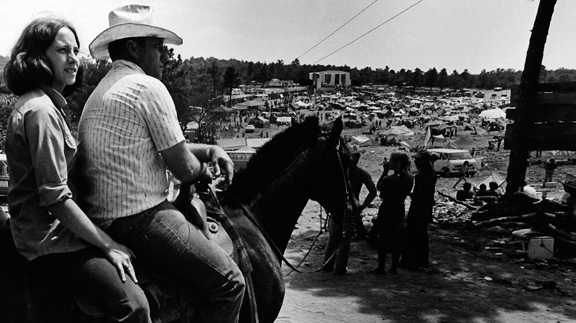

I knew a fellow named Ray Moore, who had a ranch in Hartsel, Colo. He was a Longhorn breeder, and I got acquainted with him. He wanted us to send some yearling steers out to Hartsel, Colo., to summer. I told Jake about the Colorado deal. Jake was interested in going in partners with us, and we would send some cattle out there to summer. We thought we should go out and look at the grass before we sent any steers there. We decided to fly to Hartsel and look at the pasture.

Jake had a good friend named Charlie Williams in Fairview. Charlie was Jake’s banker, and he flew a lot. He told Jake if he ever needed to go anywhere he knew a good charter service in Oklahoma City that would fly us. We decided to have Charlie contact this flying service in Oklahoma City, and we would fly to Hartsel, Colo. We had to fly into Colorado Springs, Colo., the closest airport. Hartsel was just a small place.

The charter service had an Air Commander, which is a twin-engine plane. Jake thought that this was what we would be flying to Colorado Springs in. We met at the Fairview Airport early one morning, and we waited around there for a short while. Soon this little airplane came in, actually, it was a fair-size airplane, but it wasn’t a twin engine: it was a single engine Air Commander. It was a pretty nice airplane. We didn’t have any second thoughts. We got on board. There was a young kid flying it, and come to find out, he had just got out of the Air Force the day before and was used to flying jets. I think this was on a Monday morning, and he had applied for a job flying charter service for this company in Oklahoma City. This was his first job.

Somewhere in western Kansas he got to fooling with the radio. We found out that we didn’t have any radio contact with anybody. We couldn’t talk to anyone at the towers or anywhere, but this kid said, “We’ll be all right.” I said, “How are you going to let them know when we get to Colorado Springs that we want to land?” And he said, “Well, there is a procedure that we can do to let the tower know that we want to come in for a landing.” So, we finally arrived at Colorado Springs and sure enough he flew over the tower and gave some sort of signal, and they gave us the green light to come on in and land.

Our pilot wasn’t used to flying this sort of airplane. I was sitting in the front seat. When we came in, he landed too hard on the nose wheel and the wheel gave way, bending the propeller. It almost came back into the windshield where I was sitting. It liked to scare us to death. Here we sat in the middle of a busy airport with a busted nose wheel and a propeller bent back almost into the windshield. They came out and pulled us off of the runway with a vehicle. I told our pilot that Jake and I will just take a commercial airliner back to Oklahoma City, and somebody can meet us there. The pilot said, “There’s no need. They’ll have to fly out to pick me up, and you might as well ride back with us. There’s no need spending money for tickets.”

We had kind of mixed emotions on whether we wanted to do that or not. Anyway, he said, “Why don’t you go on out and do what you have to do and call me at the office, and I’ll see what they want to do. I’m sure they’ll send a plane out, and you might as well ride back with us.”

We rented a car and drove to Hartsel, which is probably 50 miles or so, I don’t remember exactly. We got there and looked at the pasture. I called back to the Colorado Springs Airport and got a hold of this kid, our pilot. He said, “They’re going to send a plane out, and they’ll pick us up here at the airport about 3:00 p.m.” We had to hurry to get back. We just knew they were going to send that twin engine Air Commander out to pick us up.

We got back in to Colorado Springs and checked in our car and went into the terminal and waited. He said, “We’ll pick you up in front of the terminal doors there.” We walked up to the terminal and looked outside, down the runway. There was an Air Commander sitting there and Jake said, “There’s the plane we’re going to fly back in, I bet.” And I said, “Well, I hope so.” So we stood there a little bit and looked up and down the runway. Pretty soon here came this little, bitty airplane that looked like a kite. It pulled up right in front of the door and there sat our pilot, the one who had flown us out, and another kid younger than our pilot, flying the plane. They taxied right up there where we were standing and opened the door on their little ole airplane and said, “Well, are you ready?”

Jake and I kind of looked astonished. I didn’t know how in the world all four of us were going to get in that little airplane. We stammered and stuttered around there, and Jake or I said, “Well, are you sure we can all ride back in that little ole airplane?” And this kid said, “Oh yes, we’ve got plenty of room.” Well, Jake was a big guy. He probably weighed 260 pounds, and he had a big ole sheep-lined coat on. And I was pretty well dressed, as it was cold. They said, “Get in.” So there was nothing we could do but get in. They had taxied right up where we were standing, and we could hardly say we weren’t going to go. We managed to get in.

Jake got in, and he took off his big coat. I got in and sat on his lap, almost. We were crumpled up in this little Drummond Airplane. It must have been the littlest airplane they ever made. Jake still had mixed emotions and said, “Are you sure this is all right?” This kid said, “Yes, we’re all right.” We all got in this thing, and we taxied way down to the north end of the runway. We took off, but we could not get that thing off of the ground. Every time the pilot tried to get some altitude, a beeper would go off. Finally, Jake said, “Why don’t you turn around and we’ll get off.” This kid said, “No, if we can get some altitude, we’ll be okay.” We finally got enough altitude to get over the fence posts. I don’t know how far we flew at this low level, just missing the tops of the fences.

Here we were in Colorado Springs, pretty open country, and why these kids did this I’ll never know. But anyway, we finally got into the air and we were flying into the southeast. I don’t think we ever had a southeast wind before, but that day, after we flew and finally got some altitude, we were flying right into the southeast wind. I think we left Colorado Springs about 3:00, I’m not for certain. We flew and we flew and we flew. I think we could have walked faster than we were going, because here we were overloaded and flying into the wind. About 6:00 p.m. we went over Two-Buttes, Colo. It took us about two hours to get there. We could have driven in a car there faster.

Read the October issue to learn more!

Farm & Ranch

Fescue Foot

Barry Whitworth, DVM | Area Food/Animal Quality and Health Specialist for Eastern Oklahoma

*Article originally printed in the October 2022 issue of Oklahoma Farm & Ranch.

Since most of Oklahoma experienced drought conditions and with fall fast approaching, producers with fescue pastures should closely observe their livestock for any signs of fescue toxicity. According to Mike Trammel, Pottawatomie County Ag Educator and Muti-County Agronomist, fescue toxins (ergot alkaloids) tend to increase in Kentucky-31 tall fescue pastures in the fall. Some reports indicate more problems with fescue toxins following a summer drought and limited fall rains. All of this may put Oklahoma cattle at a greater risk of fescue toxicity.

One issue that cattle experience with fescue toxins is fescue foot. Fescue foot is thought to be caused by ergot alkaloids such as ergovaline. These alkaloids are produced by endophyte fungus (Epichloë coenophiala) which is in tall fescue. Ergovaline has been proven to be a vasoconstrictor which might be responsible for fescue foot and heat intolerance also known as summer slump in cattle. Other issues that may be seen with the ergot fescue toxins are reduced milk production and reproductive issues.

Clinical signs of fescue foot appear within a few days of cattle being turned on to tall fescue pastures or it may take weeks if toxins in the pasture are low. Producers will initially observe cattle with arched back, rough hair coats, and sore feet. These symptoms are more noticeable early in the morning and with cold weather. This is followed by reddening and swelling in the area between the dewclaws and hooves. The lameness usually becomes more severe with time. If no action is taken, gangrene will result in loss of tissues distal to the coronary band and declaws. If the weather remains mild, other signs such as increase respiration rate, increase heart rate, and higher body temperature are more common.

Other causes of lameness in cattle must be differentiated from fescue foot. One simple method that will help differentiate fescue foot from footrot is to check the temperature of the foot. If the foot is cold, this is an indication that the problem is more likely fescue foot.

Since there is not a specific treatment for fescue foot, the condition must be managed. Cattle need to be observed daily for any signs of lameness or stiffness during the first few weeks on fescue pastures. This should be done early in the morning before cattle walk off the stiffness. Producers should pay close attention during cold weather, especially when rain, snow, or ice are present. Any animal showing clinical signs of fescue foot should be removed from the pasture and placed in a clean environment. The animal should be fed a ration with no fescue toxins.

The best but most costly solution to reduce fescue toxicity is to renovate old pastures with new endophyte friendly varieties. If this option is not possible, producers might try interseeding fescue pastures with clovers or other grasses. This should dilute fescue toxins. Nitrogen fertilization may increase ergot alkaloids, so producers should avoid fertilizing fescue pastures with high amounts of nitrogen. Researchers have demonstrated that feeding a supplement while grazing fescue pastures reduces clinical symptoms. Some studies indicate a difference in susceptibility to fescue toxicity in some cattle. Selecting cattle based on genetic tolerance of fescue toxins is an option. (For more information go to www.agbotanica.com/t-snip.aspx)

With large areas in Oklahoma covered with Kentucky-31 fescue pastures, fescue foot as well as other fescue toxicities are not going away any time soon. Livestock producers will need to watch their livestock closely for any signs of fescue toxicity and manage their pastures to keep toxins as low as possible. If producers would like more information on fescue foot, they should consult their veterinarian and/or visit their local Oklahoma State University Cooperative County Extension Agriculture Educator.

Farm & Ranch

Animal Disease Traceability

Barry Whitworth, DVM, MPH | Senior Extension Specialist | Department of Animal & Food Sciences | Freguson College of Agriculture

On July 6, 2020, the United States Department of Agriculture (USDA) Animal and Plant Health Inspection Service (APHIS) posted in the Federal Register a proposal that radio frequency identification tags be used as official identification for cattle and bison. Following a period for public comment, the USDA APHIS released a statement on April 24, 2024, with the amended animal disease traceability (ADT) regulation for cattle and bison. The full press release may be found at https://www.aphis.usda.gov/news/agency-announcements/aphis-bolsters-animal-disease-traceability-united-states. Under the new rule, cattle and bison will need to be identified with tags that are both visual and electronic.

The USDA defines ADT as knowing where diseased and at-risk animals are, where they have been, and when the animal disease event took place. A system that allows for efficient traceability of livestock in the United States (US) is essential for animal health and reducing the economic effect of a foreign animal disease outbreak and other diseases on livestock producers as well as others whose well-being depends on livestock production.

In the past, the USDA used metal tags commonly referred to as “Brite” or “Silver” tags to officially identify cattle and bison. Also, cattle and bison vaccinated for brucellosis were tagged with an orange USDA metal tag. Recently, the USDA recognized electronic identification (EID) as an official ID. Under the new rule, cattle and bison needing an USDA official ID will be tagged will an EID.

According to Dr. Rod Hall, State Veterinarian of Oklahoma, the average cattle producer will not notice any change under the new rule and will not have to do anything differently than they are currently doing. The rule does not require mandatory tagging of cattle on a farm or ranch. Livestock auctions will continue to tag cattle that require an official USDA ID. The only change is that an EID will be used instead of a metal tag. The classes of cattle and bison requiring USDA official ID have not changed. The classes are:

Beef Cattle & Bison

- Sexually intact 18 months and older

- Used for rodeo or recreational events (regardless of age)

- Used for shows or exhibitions

Dairy Cattle

- All female dairy cattle

- All male dairy cattle born after March 11, 2013

Other common reasons that cattle and bison require USDA official ID include disease testing for brucellosis or tuberculosis and movement from one state to another state. Also, brucellosis or calfhood vaccination of heifers require official ID. The official USDA ID will be an EID starting November 2024.

If a cattle producer would like to tag their breeding cattle, electronic ID tags are available from Dr. Rod Hall. Producers will have to pay the shipping cost but the tags are free. The order form is available at: https://ag.ok.gov/wp-content/uploads/2023/04/MULTI-TAG-ORDER-FORM-v8.23.pdf. Producers with questions should call Oklahoma Department of Agriculture, Food & Forestry at 405-522-6141.

Change is usually hard. Changing how cattle and bison are officially identified will be difficult for some cattle producers. However, in the event of a disease outbreak, the use of EID should make the traceability process more efficient which is a good thing.

Producer wanting more information on the USDA amended rule on animal disease traceability should go to: https://www.aphis.usda.gov/livestock-poultry-disease/traceability#:~:text=A%20comprehensive%20animal%20disease%20traceability%20system%20is%20our,sick%20and%20exposed%20animals%20to%20stop%20disease%20spread.

Farm & Ranch

Cattle Nematodes (Worms)

Barry Whitworth, DVM | Senior Extension Specialist | Department of Animal & Food Sciences

According to the Mesonet, Oklahoma received some much-needed rain in late April (2023). With the moderate temperatures and high humidity, the environment is perfect for the proliferation of gastrointestinal nematodes (GIN) which are commonly called “worms.” Cattle can be infected with a variety of GIN. Most do not cause issues unless husbandry practices are poor. However certain GIN have been associated with disease. The most pathological GIN in cattle is Ostertagia ostertagi. Cooperia species and Haemonchus species are two that have been implicated with production issues. Control of these parasites is constantly changing due to environment, anthelmintic (dewormer) resistance, and consumer preference. Cattle producers should develop a plan to manage these parasites.

In order for GIN to complete their life cycle, certain environmental conditions must exist. The development stage begins with passing of the egg in the feces of the animal. If the egg is to hatch, the temperature must be warm and the humidity needs to be close to 100%. Ideal temperature ranges from 70⁰ to 80⁰ Fahrenheit (F), but any temperature above 45⁰ F will allow for development. Temperatures above 85⁰ F or below 45⁰ F will begin to hamper development. Humidity needs to be 80% or higher.

Once the egg hatches, the larva goes through a couple of molts to reach the infective stage which is the third stage larva (L3). L3 must have moisture to free itself from the fecal pat. Once free, it rides a wave of water on to a blade of forage. Once ingested, this begins the prepatent or pre-adult stage. Two molts take place during this stage (L3 to L4 and L4 to L5). If conditions are not favorable for survivability of offspring, L4 will go into an arrested development stage (hypobiosis) for a period of time. The patent or adult stage is the mature breeding adult.

Once inside the body, the parasite will migrate to certain locations in the digestive tract. For example, O. ostertagi develop in the gastric gland in the abomasum. H. placei and H. contortus will migrate to the abomasum. Cooperia species will live in the small intestine. A few like Trichuris (whipworms) are found in the large intestine.

Clinical signs of parasitism vary according to the species of parasite, burden, and site of attachment. Severe disease, which is referred to as parasitic gastroenteritis (PGE), with internal parasites is unusual with today’s control methods. Clinical signs of PGE are lack of appetite, weight loss, weakness, diarrhea, submandibular edema (bottle jaw), and death. However, most parasite infection are subclinical which means producers do not see clinical signs of disease. In subclinical infections, the parasite causes production issues such as poor weight gain in young cattle, reduced milk production, and lower pregnancy rates.

Producers should be monitoring their herds for parasites throughout the year but especially in the spring when conditions are ideal for infection. A fecal egg count (FEC) is a good way of accessing parasite burdens. Livestock producers need to gather fecal samples from their herd periodically. The samples should be sent to their veterinarian or a veterinary diagnostic lab. Different techniques are used to access the number of eggs per gram of feces. Based on the counts, the producer will learn the parasite burden of the herd. Producers can use this information to develop a treatment plan.

In the past, GIN control was simple. Cattle were routinely dewormed. Unfortunately, anthelmintic resistance has complicated parasite control. Now proper nutrition, grazing management, a general understanding of how weather influences parasites, biosecurity, refugia, anthelmintic efficiency, and the judicious use of anthelmintics are important in designing an effective parasite management program. All of these considerations need to be discussed in detail with a producer’s veterinarian when developing a plan for their operation.

Cattle producers need to understand that parasites cannot be eliminated. They must be managed with a variety of control methods. Designing a parasite management plan requires producers to gain a general understanding of life cycle of the parasite as well as the environmental needs of the parasite. Producers should use this information as well as consult with their veterinarian for a plan to manage GIN. For more information about GIN, producers should talk with their veterinarian and/or with their local Oklahoma State University Cooperative Extension Agriculture Educator.

References

Charlier, J., Höglund, J., Morgan, E. R., Geldhof, P., Vercruysse, J., & Claerebout, E. (2020). Biology and Epidemiology of Gastrointestinal Nematodes in Cattle. The Veterinary clinics of North America. Food animal practice, 36(1), 1–15.

Navarre C. B. (2020). Epidemiology and Control of Gastrointestinal Nematodes of Cattle in Southern Climates. The Veterinary clinics of North America. Food animal practice, 36(1), 45–57.

Urquhart, G. M., Armour, J., Duncan, J. L., Dunn, A. M., & Jennings, F. W. (1987). In G. M. Urquhart (Ed). Veterinary Helminthology. Veterinary Parasitology (1st ed., pp 3-33). Longman Scientific & Technical.

-

Country Lifestyle7 years ago

Country Lifestyle7 years agoJuly 2017 Profile: J.W. Hart

-

Outdoors6 years ago

Outdoors6 years agoGrazing Oklahoma: Honey Locust

-

Country Lifestyle3 years ago

Country Lifestyle3 years agoThe Two Sides of Colten Jesse

-

Outdoors4 years ago

Outdoors4 years agoPecan Production Information: Online Resources for Growers

-

Equine7 years ago

Equine7 years agoUmbilical Hernia

-

Attractions7 years ago

Attractions7 years ago48 Hours in Atoka Remembered

-

Farm & Ranch6 years ago

Farm & Ranch6 years agoHackberry (Celtis spp.)

-

Outdoors3 years ago

Outdoors3 years agoSuzy Landess: Conservation carries history into the future